Siemens Xcelerator and Digital Twins add instant supply chain information capabilities

Siemens Digital Industrial Software has launched a new integrated solution that combines Supplyframe™'s Design-to-Source Intelligence (DSI) platform with Siemens Xcelerator's software and services product portfolio to add real-time supply chain information to digital twin technology.

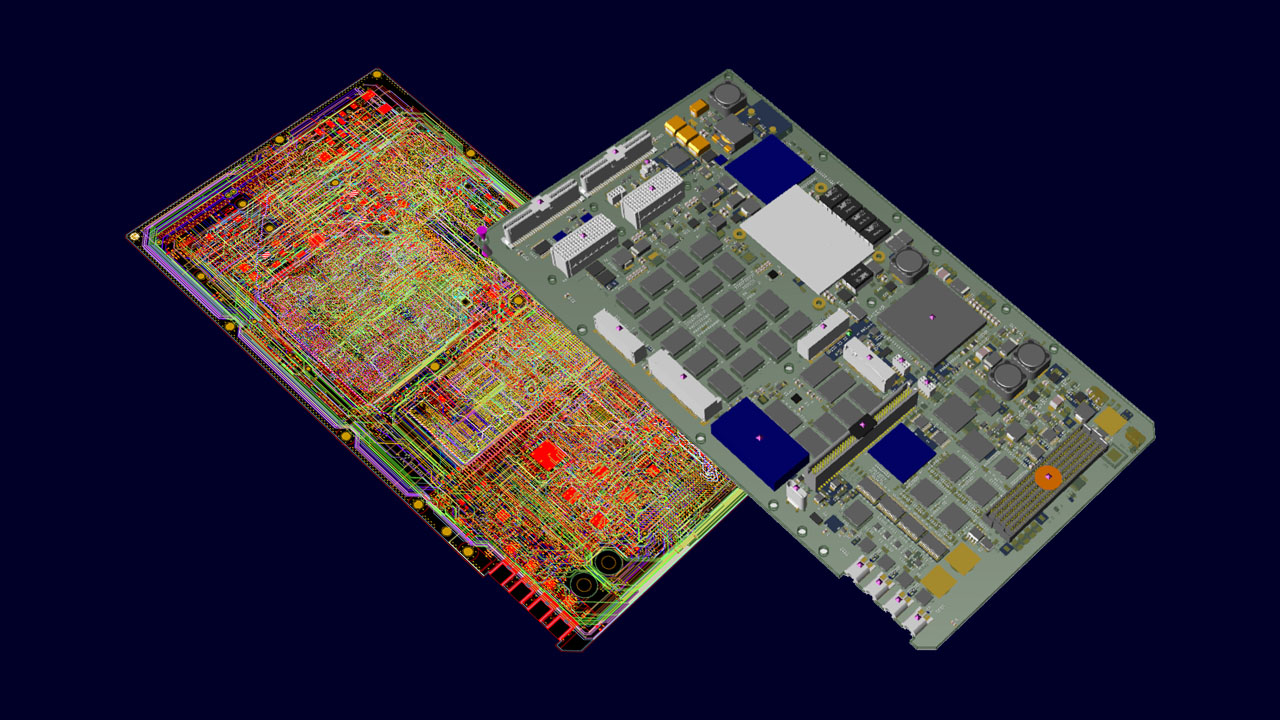

The solution uses Supplyframe's integration with Siemens Xpedition™ electronic system design software as an entry point to provide real-time visibility into global component availability, demand, cost, compliance and related parameter data at the design stage to enhance supply chain resilience.

The solution builds on Siemens' strengths in printed circuit board (PCB) design and analysis technology, coupled with Supplyframe's in-depth market analysis capabilities, to help customers reduce costs and increase flexibility to make informed component decisions at the design stage. By synchronizing data from the Product Lifecycle Management (PLM) and Electronic Computer Aided Design (ECAD) domains, it helps engineering design teams streamline the component selection, creation and management process in the design of electronic systems.

AJ Incorvaia, Senior Vice President of Digital Industrial Software Board Systems at Siemens, said: "In recent years, the market has been characterised by complex dynamics, which pose demanding challenges for our OEM customers. Complex geopolitics, a globally spread portfolio and supplier distribution, and the pressure for rapid new product development and time-to-market have made the global supply chain increasingly unpredictable. Siemens has integrated Supplyframe's DSI platform with Xpedition electronic system design software to provide customers with the relevant tools and technology to help them face the challenges head-on."

Supplyframe, acquired by Siemens in 2021, is the leading platform for Design-to-Sourcing Intelligence (DSI) solutions across the global electronics value chain, helping electronics manufacturers and distributors accelerate new product launches, reduce supply chain risk and capitalise on market opportunities through intelligent software and industry vertical solutions. Supplyframe's DSI platform has real-time global supply and lead time information for over 600 million components and captures billions of component supply, demand, risk and commercial intent data signals.

The solution also creates a range of features and usage scenarios for engineering design teams developing next generation PCB designs, including

One-click access to detailed component information for over 600 million manufacturer component numbers, helping engineers make more informed component decisions and trade-offs while significantly reducing change costs.

Eliminates manual data entry and device library maintenance tasks.

Provides detailed component comparison views, 'what-if' component selection analysis and digitally managed workflows.

Enables seamless, real-time component-level auditing to simplify risk assessment during design entry.

To remain competitive in a changing global business environment, companies must be able to quickly adapt their design and procurement strategies," said Steve Flagg, founder and CEO of Supplyframe, a Siemens business. The launch of this solution further extends Siemens' leadership position in supply chain resilience. The Siemens Xcelerator portfolio facilitates robust collaboration between engineering design teams, NPI management teams and procurement teams, while providing built-in resilience capabilities and decision support for all stakeholders in the modern digital enterprise."

Siemens' Xpedition software is the industry's innovative PCB and electronic systems design and development solution, providing comprehensive support for engineering, design, analysis, manufacturing and data management.Xpedition provides a PCB design flow from system design definition, electronic design, electromechanical co-design, analysis and verification, through to PCB manufacturing. Its unique, patented technology can reduce design cycle times by 50% or more, while improving overall quality and resource management.